6 Supplier Quality Management and Production Part Approval Process

6.1 Introduction to Supplier Quality

6.1.1 Supplier Quality Overview

Significance of Suppliers

In today’s world, few product producers or service providers can do all the work for their customers because of various reasons, such as business focus, financial constraint, and technical expertise. An organization often outsources some supportive functions, and even a small segment of core functions, to its suppliers.

For a manufacturer, a supplier may provide raw materials, production parts, and service parts. A supplier may also handle some specialized manufacturing processes of products, such as casting, heat-treating, and surface finishing. On the service side, a common example is an IT function that can be outsourced to a professional provider. All the outsourced functions and suppliers play an integral role to the product or service quality experienced by customers, as discussed in earlier chapters.

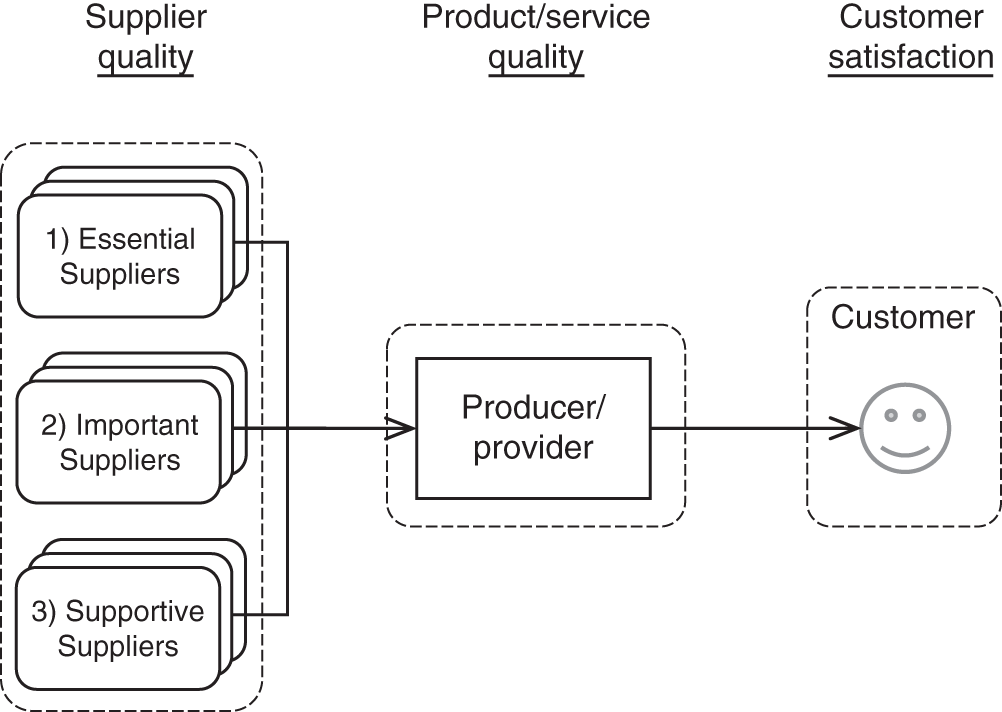

Depending on the significance of suppliers’ work and their deliverables to a producer or provider, their roles may be categorized into three levels (see Figure 6.1). Their significance levels can be determined based on functionality, operation, quality, etc. by a producer or provider.

Figure 6.1 Roles of suppliers to producer/provider and their ultimate customers.

- Essential: These suppliers are the crucial ...

Get Quality Planning and Assurance now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.