7Burn-In Test

As already noted, a product that is in the manufacturing stage may typically have youth failures, notably during the first years of operation. Moreover, a product is considered mature provided that it has a constant reliability level that is higher than the specified objective. Prior to being delivered to the system manufacturer, the product should therefore be subjected to a test referred to as a burn-in test (Kececioglu and Sun 1999). The aim of this test is to eliminate as much as possible the defects generated during the manufacturing stage. It is conducted on each of the products delivered, as the manufacturing process may have certain variability and evolve (change of equipment, testing process, operator, variability in the testing means, etc.) in time throughout the period of product delivery.

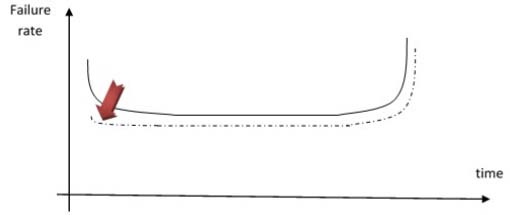

Figure 7.1. Burn-in test effect on product reliability

In fact, for the method chosen in this book, this test is part of a more comprehensive method, namely the HALT/HASS method, which involves two distinct stages:

- – HALT testing strictly speaking involves finding the operational or environmental limits of the product in terms of thermal and vibration constraints;

- – HASS testing involves the burn-in stage.

Burn-in testing presents a challenge, however. The maximum elimination of latent youth defects at reasonable costs (notably the testing duration) requires the ...

Get Product Maturity 1 now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.