1

Although the actuator will automatically

stop when it gets to the end of its travel,

this crushTime period (30 seconds for

my motor) sets how long the motor

should be on, before reversing.

2

The setup function controls the whole

operation of the project. After setting

both control pins to be outputs, it

immediately starts the crushing action

using the crush function.

4. SMASH CANS!

Push the Reset button on the Arduino

to trigger the crushing action (Figure

C

). Whenever the Arduino resets, it

automatically starts to move the linear

actuator. Smoosh!

GOING FURTHER

H-bridges can be used to control other

types of motors, including stepper motors.

They can also be used to switch power to

other devices, such as Peltier heating and

cooling elements. You’ll learn all this and a

lot more in my book, Make: Action.

Simon Monk

Hep Svadja

makezine.com 79

makezine.com/52

Watch the prototype crusher in action at makezine.com/go/arduino-can-crusher and

learn more about making movement, light, and sound with Arduino and Raspberry Pi in

the book Make: Action, available at makershed.com.

Time Required:

24 Hours

Cost:

$40–$60

Materials

» Arduino Uno microcontroller board

» Linear actuator, 6" stroke, 12V 3A Find

them on eBay.

» H-bridge module with L298 chip from

eBay. If your actuator’s maximum current

is not 3A, choose a different H-bridge

module (and power supply) that will cope.

» Jumper wires, female to male (2)

Adafruit #826

» Jumper wires, male to male (4)

Adafruit #758

» Adapter, female barrel jack to screw

terminal Adafruit #368

» Power supply, 12V 3A Adafruit #352

» Wood, 2×4

» Plywood, scraps

» Wood screws

Tools

» Woodworking tools

SIMON MONK

(simonmonk.org) writes books

about electronics for makers,

including Programming

Arduino (Maker Media)

and The Raspberry Pi Cookbook. He

and his wife, Linda, make and sell kits to

accompany his books at monkmakes.com.

HBridges

An H-bridge is a simple circuit that

uses 4 switches to change the

direction of a DC motor (forward or

reverse)

by simply

reversing the

polarity of

the motor’s

connections.

With all

4 switches

open, no current can flow through the

motor. However, if switches S1 and S4

are closed, but S2 and S3 are open (as

shown here), current will flow from

the positive supply to terminal A of the

motor, through the motor and S4 to

the negative supply, and the motor will

turn in one direction.

If S1 and S4 are now opened and

S3 and S2 closed, the positive supply

will be applied to terminal B instead

and flow out through the motor and S2

to reverse the direction of the motor.

Interestingly, you can brake the motor

by closing S1 and S3 simultaneously

(or S2 and S4). Just don’t close S1 and

S2 at the same time (or S3 and S4) or

you’ll cause a short circuit!

The L298 chip in your H-bridge

module contains 2 miniature H-bridge

circuits that work in exactly this way.

+V

S1

A B

M

S3

S2 S4

-V

An

H-bridge

using

switches.

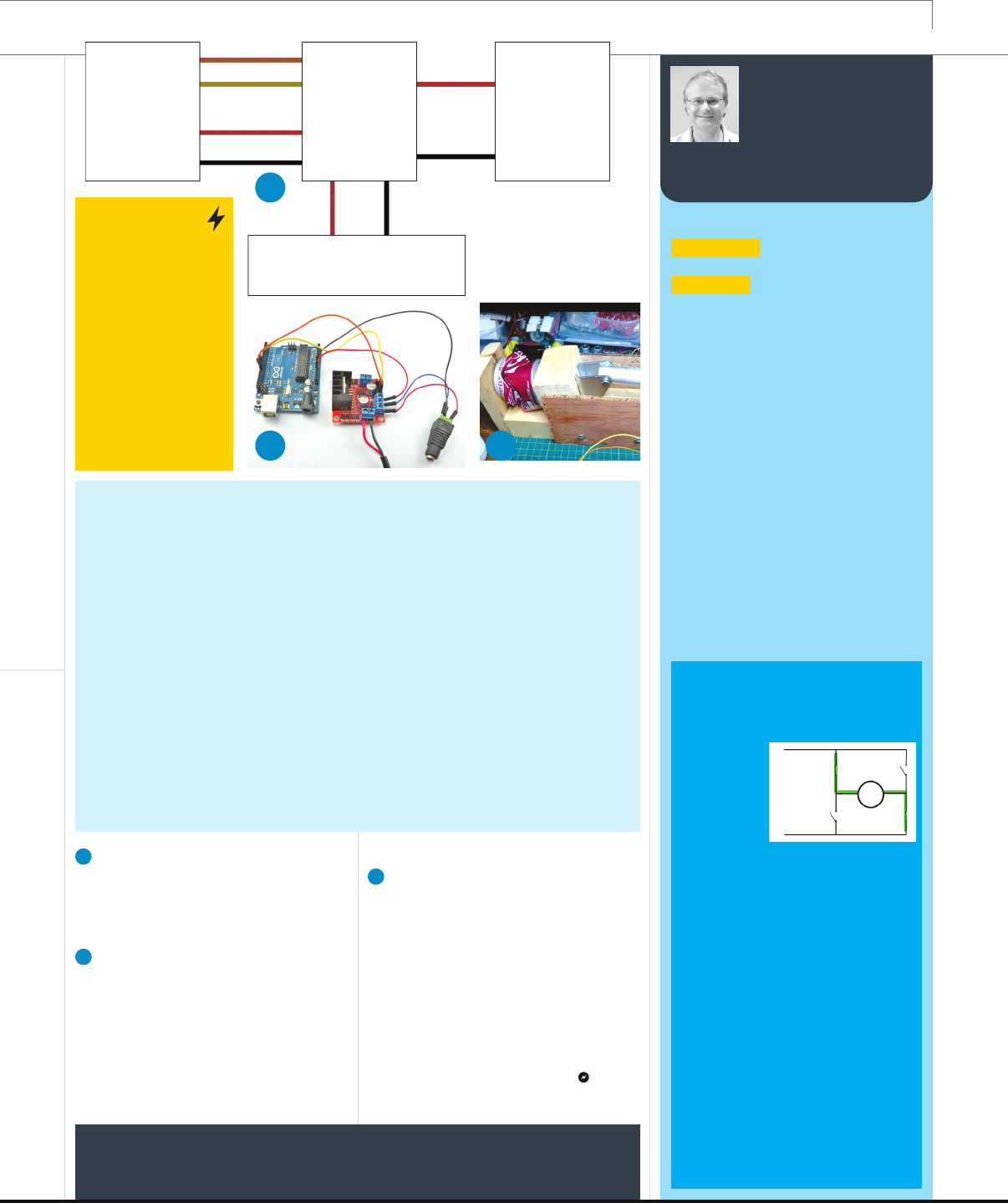

Arduino

D10 IN1

OUT1 OUT2

D9 IN2

5V

12V

GND

GND

12V DC

power supply

L298

H-bridge

module

Linear actuator

A

B C

CAUTION:

Linear actuators are

strong. This project

is about crushing

beverage cans, but

the actuator will quite

happily crush a hand or

anything else that you

put into the crushing

area. So be careful,

especially while you’re

getting it to work, when

there is a temptation to

adjust and intervene.

Imagine a car driving along and then suddenly

being thrown into reverse gear — that’s pretty

much what you’re doing if you suddenly reverse

the direction of a motor. For small motors

without a great deal of mass attached to them,

this isn’t normally much of a problem. But you

may find that if you’re using a Raspberry Pi or

Arduino board that’s powered from the same

power source as the motors, then the Pi may

crash or the Arduino may reset. This happens

as a result of the large current that flows when

you suddenly switch directions, causing the

board’s power supply voltage to dip.

For larger motors that are driving something

with a lot of inertia, sudden changes in speed or

direction can cause big problems. The resultant

large currents may damage the H-bridge,

and there’s also the mechanical shock to the

bearings of the motor.

This is something to bear in mind when

designing control software for larger motors.

One way to be nicer to your motors is to precede

any change in direction by setting the control

lines to let the motor stop, pausing for enough

time for it to actually stop before setting it

running again in the opposite direction.

In Arduino, setting up this kind of delay

function might look something like this:

forward(255);

delay(200);

reverse(255);

In our can crusher code, you can see we’ve set

full stops and also a delay of 1 second (1000

milliseconds) between crushing and reversing.

Be Nice to Your Motors

M52_078-9_CanCrush_F1.indd 79 6/14/16 11:12 AM

Get Make: Volume 52 now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.