LOGISTIC S & SUPPLY CHAIN MANAGEMENT

116

‘Time to market’ and ‘time to volume’ are powerful metrics employed by com-

panies such as Sony and Canon where short life cycles dictate a focus on rapid

response to fast-changing technologies and volatile customer demand.

In the past, the focus of many companies was primarily on efficiency, i.e. a con-

tinuing search for lower costs, better use of capacity, reduced inventories and so

on. These are still worthy goals today but the priority has shifted. Now the empha-

sis must be on effectiveness. In other words the challenge is to create strategies

and procedures that will enable organisations to become the supplier of choice

and to sustain that position through higher levels of customer responsiveness. This

is the logic that underpins the concept of the agile supply chain.

A routemap to responsiveness

The shift in the balance of power in the distribution channel has highlighted the

need for the business to be driven by the market rather than by its own internal

goals. However, for organisations to become truly market-driven, there has to be

a sustained focus on responsiveness across the business and its wider supply

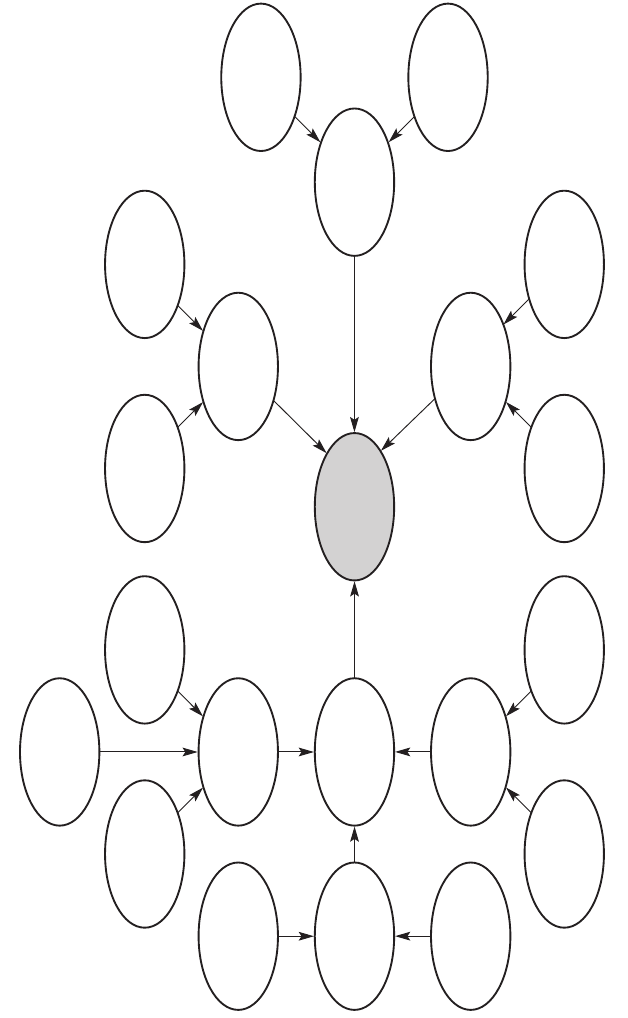

chain. There are many prerequisites for responsiveness and Figure 5.14 summa-

rises the key elements.

The responsive business will have agile suppliers and will work very closely

with them to align processes across the extended enterprise. It will also be very

close to its customers, capturing information on real demand and sharing that

information with its partners across the network. Internally the business will also

be focused on agility through the way it organises – breaking through functional

silos to create process teams. In terms of its manufacturing and sourcing strategy,

the responsive business will seek to marry the lean and agile paradigm through

de-coupling its upstream and downstream processes, utilising the principles of

postponement wherever possible.

Those companies that can follow this routemap will be more likely to be the

leaders in their field. More often than not, when we look at the successful compa-

nies in any market, they tend to be the ones that have demonstrated their ability to

respond more rapidly to the changing needs of their customers. The case study

that concludes this chapter underlines the challenges that organisations must con-

front as they seek to become more responsive to customer needs.

CREATING THE RESPON S I V E SU P P LY CHAIN

117

De-couple the

supply chain

Flexible

response

The

responsive

business

Quick

response

Process

re-engineering

Non-value-adding

time reduction

Set-up time

reduction

Capacity

management

Lean

production

Waste

reduction

Economies

of scale

Standardisation/

modularisation

Agile

supply

Synchronised

production

Vendor

managed

inventory

Demand

driven

Continuous

replenishment

programmes

Visibility of

real deand

Organisational

agility

Process

management

Cross-functional

teams

Figure 5.14 Routemap to the responsive business

Get Logistics and Supply Chain Management, 4th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.