3Proximity Probes are a Good Choice for Monitoring Critical Machinery with Fluid Film Bearings

By Robert X. Perez

Proximity Probe Benefits

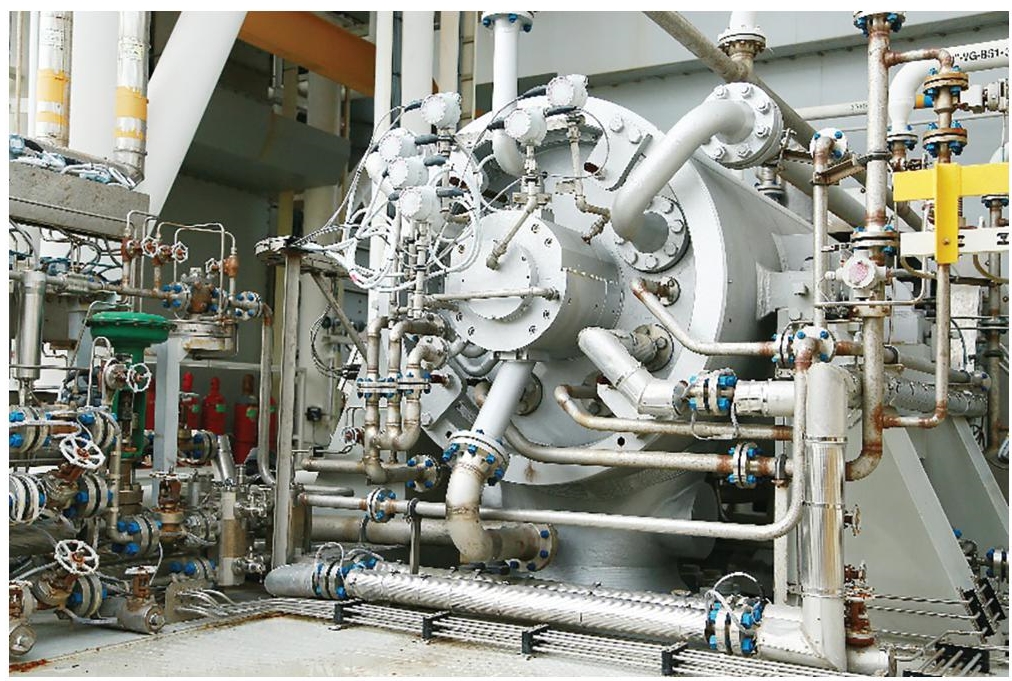

Eddy current transducers, also called proximity or “prox” probes, are frequently used to monitor rotating machinery equipped with fluid film bearings like the compressor seen in Figure 3.1. Proximity probes are especially well suited to measure the relative motion between the shaft and the bearing housing (see Figure 3.2). When properly installed, proximity probes can be used to analyze bearing and rotordynamic phenomena, which would be difficult or impossible to detect with case mounted vibration probes. Proximity probes can be used to:

- Measure shaft dynamic motion relative to the bearing housing

- Identify rotor issues related to imbalance, misalignment, looseness, oil whirl, etc.

- Assist in identifying rotor critical speeds

- Determine the relative phase relationships of rotor mode shapes by comparing phase measurements across a machine train

- Determine the relative axial position of rotor, i.e., thrust bearing monitoring, relative to the casing

Today, most critical process machines have internally mounted proximity probes at each bearing to ensure they have a clear view of bearing journals. However, in some instances, probes can be temporarily mounted close to bearings for testing purposes.

Figure 3.1 The barrel-type, centrifugal gas compressor ...

Get Condition Monitoring, Troubleshooting and Reliability in Rotating Machinery now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.